Our story chapter 2: Coding & Marking and why tailor made solutions are a rip-off

Chapter two: Less software!

Picture this: You’re in the middle of the jungle with thick vegetation and need to find a way out. What would be the quickest and best way to get you there? Option 1, machete your own way out, or option 2, use a path that someone has walked before you? Now, assuming that you picked option 2 (which I hope for the rest of this story to make sense), a paved path will indeed be quicker. Not only that, but also the more people that walked the path, the wider and easier it will be to walk on yourself. Well, in Coding & Marking the same applies when a company has a specific coding need that requires a tailored solution: Either it’s custom made and implemented from scratch or……copy-paste.

Now please don’t get me wrong. Custom solutions are great! After all each company has its own unique Coding & Marking needs and goals. Goals that, as mentioned last time, are primarily about cost reduction. And since late generation printers all have very similar mechanical specs, the best way to become preferred supplier nowadays is through software and automation. Until now however high levels of automation have only been accessible to companies with deep pockets and big patience. Just read between the lines when a printer leaflet says “in-house made software”. Isn’t the leaflet really just telling the customer: If what you’re asking is new to us you are more than welcome to pay us to find out how to do it. O yeah, and after that we’ll keep the meter running just in case you actually want it to work properly too.

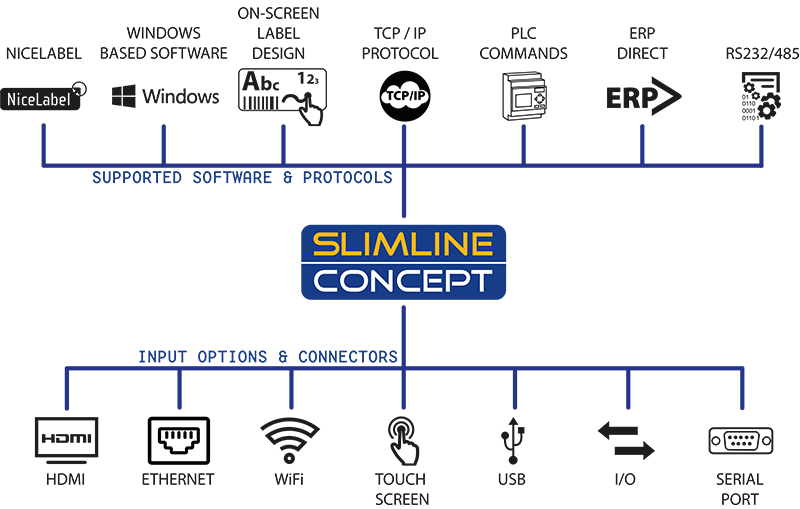

So wouldn’t it be an amazing USP to be able to implement any tailored software solution, but for the price, speed and stability as if it were a standard copy-paste feature? And thus bringing a SMART and automated coding process within reach of everyone? How? Simple, just have your equipment work plug & print with the protocols, software and platforms that have the biggest user base! The more users, the bigger the chance that someone has done it before and you can re-use at least a great part of it. Worst case something might have to be configured, but never made from scratch, tested and then fine-tuned and maintained. It really is a simple case of “if you can’t beat them, join them”. And no coding equipment manufacturer has a software department that can compete with all the companies out there who create software as their core-business!

And so, joining them is exactly what we did at Kortho: All our SLIMLINE printers (starting with our T-Series thermal printer) will basically be full Windows industrial computers with a printhead attached to them. This makes every single Windows based software and/or function compatible with our equipment! The idea is that our printers should be able to be integrated directly into any existing production process, no matter what it looks like or how it’s organized. No more lock-you-in, one trick, one brand, custom made software, but an open and standardized system that will play along with anyone and everything. Meaning that (in accordance with our Smart Less Is More philosophy) also on tailored solutions we add More value through Less implementation costs.

But it’s not only because of cost reduction that we chose this product strategy. Just also think of all the Windows based software, functions and tools that we will be able to use! Stuff that for coding equipment is exotic, but are all standard functions for PC’s. Things like having a printer send an email to the operator when the ink/ribbon is running out, or logging into the printer through the internet so a customer can be helped remotely. It’s even theoretically possible to sing Karaoke or watch a movie on our controller! (although for obvious reasons we’re not putting that in there). But you get the point: Everything a PC can do, our printer will too! So whatever tailored solution a customer might need, we’ll have it: Cheap, quickly implemented and working great straight off the shelf!

And so with the end of this second chapter yet another element of our new SLIM printer line is slowly but surely unveiled. So let’s recap on how in Coding & Marking indeed by being Smart, Less Is More:

Chapter one: Less costs!

Chapter two: Less software!

Chapter three (next time): Less hardware!

Chapter four: Less secrecy & full disclosure!

Nooit meer duur en fout coderen met de Kortho

Nooit meer duur en fout coderen met de Kortho