Industry 4.0: What’s in it for Coding & Marking?

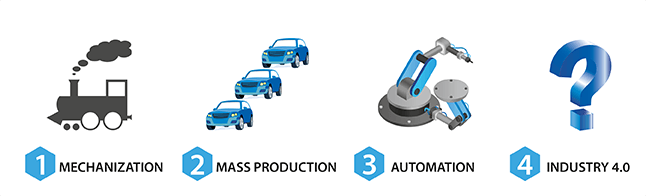

Industry 4.0 and IoT: The latest hot topics on the industrial section of the internet. We all know by now that Industry 4.0 revolves communicating machines and that it’s the fourth industrial revolution after the steam engine(1), assembly line(2) and computers(3). But what does it really mean? And more importantly, what’s in it for Coding & Marking? As true evangelists of the network controlled coding process Kortho is happy to explain its benefits and what functions to look out for in a true Industry 4.0 printer.

What’s so new about an Industry 4.0 printer then? Surprisingly, not that much! You see, the whole IoT and Industry 4.0 hype is about machines and devices that communicate through TCP/IP, where IP stands for Internet Protocol (Hence: Internet of Things). In the case of Coding & Marking this means less stand-alone operation and more centralized control of printers.

So, where before printers would be configured manually on their own touchscreens, now all labels and printjob parameters can also be sent directly to the printers through a network connection. These print parameters could for example originate from a ERP system, a (cloud) server, a production PC or even a mobile device. But also other “smart” industrial machines like checkweighers or quality control equipment can now tell a printer what to do through TCP/IP. Naturally the communication goes both ways so the printers can also report back their status in real-time. That’s basically it.

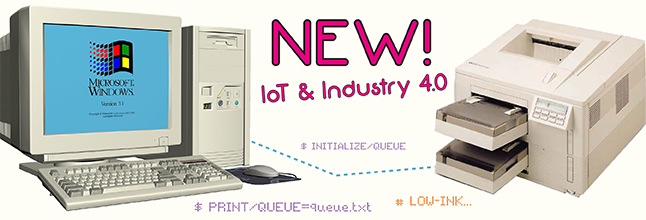

And since office printers have been controlled like this for decades it’s hardly a technological revolution just because the printers are now industrial. Do you even remember the first time that you sent a printjob from your PC to your desktop printer? Or when the printer sent a notification like “low ink” back? So yes, smart lightbulbs, espresso machines and refrigerators with an IP address are a relatively new phenomenon. But printers, no not really….

Why all the fuzz then? Well, basically two things: First is that industrial environments finally also recognized the benefits of centralized control on a mainstream level. Luckily the times when marketing departments got away sounding savvy with vague jargon about “smart machines” and “integrated processes” have passed. Now everybody sees clearly that readying an entire production line for the next job with a single mouse click really does save time, and that not having to configure machines manually really does avoid errors.

So an increasing general demand for remotely controlled factory equipment was the first step. But what actually really launched Industry 4.0 was IP technology becoming the protocol of choice for it all. All of the sudden implementing custom solutions became standardized!

Where in the past equipment communication and tailored solutions had to be tied together through many different exotic protocols, work-arounds and custom scripting, now a smart and client specific manufacturing process is available plug & print. So industry 4.0 isn’t necessarily about a new technological breakthrough. It’s about the global recognition of the benefits of centralized control in combination with TCP/IP making them available off the shelf and therefore not just only for the patient and wealthy anymore.

IF (and here it comes) you have the right equipment…

And so, stay tuned to find out exactly, feature for feature, if you are dealing with a true Industry 4.0 machine!

First two Industry 4.0 features to be discussed next time:

- Centralized Control

- Database Publishing

From: LinkedIn Kortho Coding & Marking posted 5 November 2018