Food production

Coding of food products

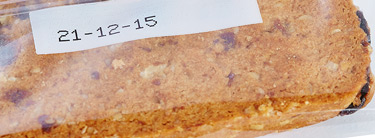

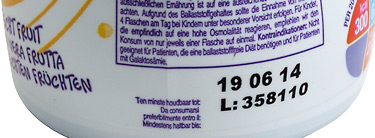

Coding in the food industry is regulated by very strict legislation. Coding that guarantees traceability, lists product ingredients, and also shows their best-before dates and date of sale needs to meet increasingly stringent standard requirements. In addition, these requirements can differ between countries. It is therefore essential to ensure that coding is always flawless, but also that label content can be changed quickly and easily. This to prevent coding errors which have major consequences such as fines, and/or having to repack or even recall products.

Industry focused solutions for coding food products

The solution is to ensure 100% error free coding along the entire production line (from product to pallet). This obviously starts with reliable coding equipment, but also with its correct management and control. For instance, retrieving printdata from a database or ERP and without human intervention, and even possibly checking the prints physically afterwards. Finally, working with dynamic label templates instead of multiple individual loose labels per product makes it possible to alter labels fast and in one action and for all products.