Always the correct code on salads in supermarkets

Downloads

- Original article: Supermarket salads always coded correctly

Never again coding errors at “De Menken Keuken”

Dutch family business “de Menken Keuken” produces thousands of kilograms of salads and cold cuts for the Dutch supermarkets. These supermarkets all have different demands about how their products should be labelled and coded. Especially with rapidly changing laws (like the allergen directive) this is constantly becoming more complex. Coding and labelling specialist Kortho supplied a perfect solution using Nicelabel software.

Adjustments done by yourself

New Dutch laws were the reason for “De Menken Keuken” to take another look on how to further automate their coding and labeling process. The company selected Nicelabel supplied by Kortho, a Windows based software which is not only used for label design and management, but also to control printers from. “De Menken Keuken” already have experience with Kortho since they already are their supplier of continuous inkjet machines, which were used to code on the salad trays. ‘A very important demand was that we could do adjustments ourselves and configure the software in an easy way’ says Wim van der Slot, the production manager of “De Menken Keuken”. ‘You do not want to have to contract a programmer every time a change has to be made to a label. This is expensive and takes a lot of time. Furthermore the basis of the software has to be good’. Application engineer Dick van Rijn from Kortho remembers that the wish list just kept growing and growing during the process. Finally we ended with three times the functionalities as intended in the beginning. This was a result of the endless possibilities that Nicelabel has to offer. As “De Menken Keuken” learned more about what could be done, more and more functionalities and demands were asked.

Step in between

In order to make product information available for the consumer several tools are available in the cloud. “De Menken Keuken” for example uses GS1, developed by Trustbox. This is a cloud database where labelinfo should be uploaded by production companies so that it can be accessed by consumers. To be a 100% sure that the info on the label matches the info in the cloud, “De Menken Keuken” has built in a step in between. Their ERP system first generates the ingredient declarations of their products. After this Menken uploads that info to the cloud like GS1. Van der Slot: ‘If we did not take this step in between there’s a chance that our labels do not match with what is published in the cloud, and that’s a risk we do not want to take’.

Bold, Italic or underlined

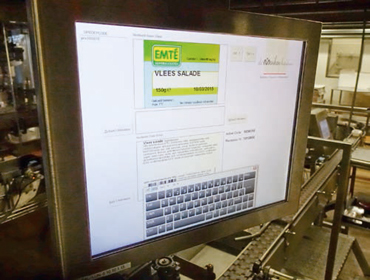

When labelling salads and cold cuts a label template is used that is made in Nicelabel. The variable label info in the label comes directly from their ERP system. This is done for two labels, one on the front of the tray and one on the back. On the label on the front the name of the product along with the weight and expiration date are printed. The ingredients, nutritional value and contact info are printed on the back. Nicelabel automatically highlights the allergens (something that has to be done by law). The way in which the ingredients are highlighted is dictated by the marketing side of the supermarket. Some want them to be printed italic, others bold or underlined or even in combinations. ‘By automating this we save a lot of time and avoid errors. The only thing the operator has to do is select the product code on the touch screen that is positioned along the production line. We do still have a manual quality inspection at the beginning and the end of every production line, to make sure the right print job has been selected, but this might also be not necessary in the future if switch to print jobs selection by scanning a barcode.

Also suitable for smaller companies

The Nicelabel application of “De Menken Keuken” is one of the more extensive Nicelabel projects for Kortho. 14 production lines have been equipped with the software. ‘It doesn’t matter if a hundred ore just one line is equipped’, says Meindert de Groot, Sales director of Kortho. Because of the economic license price and the endless possibilities of Nicelabel also smaller companies can now automate their coding and labeling process. A level of automation is now available which before could only be achieved through expensive and unstable custom programming. Even for standalone applications this could be interesting since a lot of manual work can be avoided. On top of this the Windows based aspect also guarantees a quick and easy implementation. How easy a functionality can be added or changed is proved by a new feature about to be implemented. “De Menken Keuken” will add a button onto the screen which will print a pdf directly from their source database. ‘This is something that we now can do ourselves’, says Wim van der Slot proud. ‘This is why we are very happy with the system and how it works. It doesn’t happen often that people in our company say that something directly works the way it should and without problems’.