Industrial

Coding of industrial products

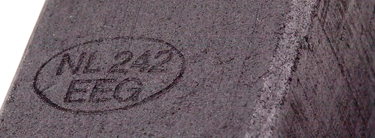

In addition to product identification and traceability, markings made after internal quality controls are also of great importance during the manufacture stages of industrial products. They ensure that parts can always be visually recognized both internally and externally. Quality is guaranteed by marking products just after an internal function test. Should a part prove to be defective, a mark is applied by which it can be recognized and, for example, be removed from the production line via a reject system.

Industry focused solutions for industrial coding

Marking for product recognition and traceability needs to be above all a flawless process. The key to this mainly lies in automating the process and excluding human error. This starts by pre-programming the print job for every product. One single product selection from a central system (PC or ERP) will configure all printers by one single action for products to be coded. To create markings after internal quality control checks, many budget contact coding solutions are available. This can be done with inks that are only visible under UV light, which leaves the products’ appearance unchanged.