Integrate Checksystem: check your codes physically

Kortho offers a full range of equipment, that can be controlled from an ERP or a central PC over the internet. This range includes Thermal Transfer and Inkjet. Individual manual line configuration is therefore no longer necessary. Especially when operating with many products/labels, or when using a lot of (different kinds of) equipment this saves a lot of time when configuring the line. Just one click of a button is enough to configure all of the equipment for the next print job.

Check your codes physically

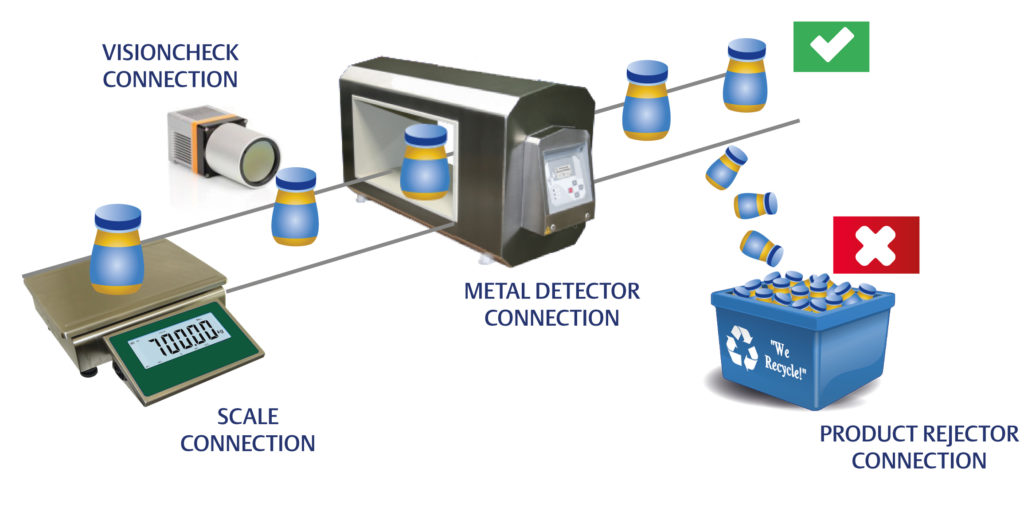

In addition to preventing coding errors by automating the coding process at the start, additional physical checks can also be implemented at the end of the line. This is done by checking equipment such as vision, weighing or measuring systems. In addition to this, external equipment can also be also used to control printers. In this case, the equipment instructs the printer what to print. A printer could then for example directly print a weight that has just been recorded by a scale, or a measured length or listed quantity from a camera system.

Plug and play integration of weighing, scanning and measuring equipment

Thanks to the standardised protocols of Kortho printers all external devices can be linked directly without the need of a custom integration. Print values from the ERP can be sent simultaneous to the printer and the checking device. If anomalies between the data and the physical print are detected after scanning/weighing, an alarm signal is generated. This alarm signal can be used to initiate an action like stopping the production line and/or show a warning on the production PC.

Please inform me!