Stencilling

How does Stencilling work?

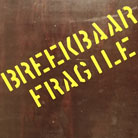

Along with the use of markers, stencilling is one of the oldest marking techniques. For stencilling, the required shape of the print is cut or die-cut out of a piece of oilboard or Mylar, thus creating a template. This is then placed onto the printing surface and coated with ink, after which the template is removed. The marking is created by the ink that is left behind on the printing surface based on the template cut out design.

Fast and economic manual coding on-site in the workplace

The correct inking method and template material for a stencil is determined by the application. Stencil template materials can include oilboard or Mylar. If a template only needs to be used a few times, oilboard can suffice. If the template needs to be more durable, then Mylar is the best option. Both are placed and inked manually onto the surface to be printed. Inking can be done with markers, rollers or paint spray cans.

Applications for Stencilling

Stencilling is still widely used in harsh environments where marking needs to be done quickly on-site/in the workplace. For instance in off-shore construction and logistics settings where crates, containers and building materials are to be marked. The same applies to the marking of crates and pallets in the tertiary stage of a packaging process. Another reason for using stencilling instead of Handcoders is its low costs, and not having to use equipment.