Leave no room for human error

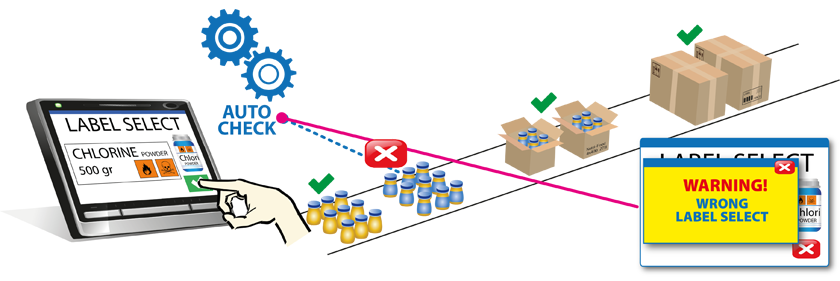

A large number of coding errors are due to human error. Such as using the wrong settings on equipment, selecting the wrong label, or a combination of both. In addition to accidental errors, an unnecessarily complicated, not user-friendly process or communication (language) barriers are common contributing factors mentioned by operators. The solution clearly lies in building in automatic checks and reducing human intervention to an absolute minimum.

Since January 2018 already 31 faulty label Recalls officialy reported at the Netherlands Food and Consumer Product Safety Authority(NVWA). A part of the Ministry of Agriculture... (31 oktober 2018)

Automatic controls, warnings and user rights

The exclusion of human error is achieved by simply allowing no more room for this to occur. This starts with an inventory of the exact steps that are to be taken in starting a production run. Those steps in which errors can occur, are then addressed. This may include warnings on the operator screen for illogical label/line selections, working with icons instead of words (for language problems) or the granting of certain rights before anything can be changed.

See also: Plug and play printer integration and custom coding solutions directly available from stock

Please inform me about Leave no Room for human error