GraphicJet X72

Downloads GraphicJet X72

- Manual: Graphicjet X-series Manual

- VIB/SDS Inks: K-GJ9/11

- MOSH MOAH Declaration K-GJ9: Mosh Moah (MOF) GJ9

- VIB/SDS Cleaner: K-GJ9/11,

- Leaflets: Leaflet Graphicjet X-series

- Video: GraphicJet Video

- Driver: KGJ X-72 Windows Driver

COMPLETELY UNAFFECTED BY HARSH OR CHANGING PRODUCTION ENVIRONMENTS

Hi-Res Piezo printers with enclosed ink systems like bottles, cans or containers are very sensitive to atmospheric changes. If for example the ambient temperature changes as much as a few degrees immediately pressure differences will build up in the ink compartment. As a result the printer will leak or, in the opposite case, starve the printhead from ink. Since the year 2000 our Piezo inkjets however have been equipped with our tried and trusted FREEFLOW(TM) inksystem. As this system is open, the internal pressure will always be equal to the external environment. This makes an X-Series totally impervious for its surrounding conditions, no matterhow demanding, harsh or abruptly changing these are.

NO MOVING PARTS, SO ALSO NO MAINTENANCE NEEDED

A second advantage of our FREEFLOW(TM) inksystem is that it needs no pumps or vales. The open and non-pressurized inktank is in direct capillary connection with the printhead. This allows the head itself to pull the exact amount of needed ink directly from the tank. Not only are pumps and valves expensive, but they are also maintenance-sensitive moving parts that wear out. Not needing them makes the printer cheaper, completely maintenance free, but more importantly gives it a bulletproof reliability. In addition the head doesn’t have to endure the fluctuating ink pressure that a pump would normally cause. As a result the printhead has a 6(!) times longer lifespan than in systems where the head does receive ink under forced pressure.

OMNICOMPATIBLE: WORKS DIRECTLY WITH ALL SOFTWARE AND ERP SYSTEMS

Where other printers only work with their own brandsoftware, Kortho leaves the choice of software completely up to you. All Kortho printers are basically industrial PC’s with a printhead. Because of this any imaginable software, connector or communication protocol is plug & print compatible and 100% industry 4.0 ready. So the use of the free label design and management software on the 20” touchscreen controller is totally optional. This makes you completely free to objectively choose the software and machine control method that’s best suited for your application. A Kortho printer adjusts itself to your coding need, and not the other way around!

SPECIFICATIONS KORTHO X-SERIES

- Unique FREEFLOW(TM) inksystem doesn’t need expensive and maintenance-sensitive moving parts like pumps and valves. Because of this Kortho Piezo inkjets are completely maintenance-free, economic to buy and have bulletproof reliability. Proof of this are the many first generation Kortho Hi-Res Inkjets used in the Dutch flower and agricultural sector. Most of them were sold as early as the year 2000 and are still in use today!

- The FREEFLOW(TM) inksystem has a non-pressurized main ink tank. In contrary to enclosed ink systems like bottles, cans or containers no pressure differences with the outside can build up in the ink compartment. This prevents ink leaks due to internal overpressure or, on the other end, ink starvation of the printhead in case of lower pressure. This makes a Kortho Piezo inkjet completely impervious to the conditions of its environment. Regardless how harsh or quickly changing these are.

- FREEFLOW(TM) allows for the printhead itself to draw the ink directly from the main tank. Because of this the printhead does not undergo constant fluctuating ink pressure. Something that would be the case if a pump would force the ink towards it. Because of this the printhead has a lifespan that’s up to 6(!) times longer than systems that do use a pressurized ink feed.

- Standardly equipped with 20cm full color Windows OS touchscreen controller.

- Label design and management software directly on controller making an extra PC no longer needed to design and manage labels.

- Unicode en TrueType font support for all system menu’s, keyboards, label elements and counters.

- Internal barcode generator for more than 113 different barcode types.

- Serialization functions for (2D) barcodes which can be generated real-time from (PLC)strings, ERP databases or from a custom string that can be freely composed using internal printer counters.

- 42 MB internal memory capacity.

- Real-time ink consumption calculation.

- Supported communication protocols: Windows network driver, RS232, PLC commands, ERP direct, BCD protocol.

- Supported connectors: Encoder, Product detection, Print request, USB, I/O, Serial port, Ethernet, BCD.

- Compatible with all Windows based software like Nicelabel, Bartender, Codesoft, SAP, Navision etc.

- Real-time printing from multiple (ERP) databases through ODBC and Loftware Nicelabel.

- Control up to 2 individually programmable printheads with 1 controller.

- X-18 en X-72 printheads can be freely interchanged with TsC20 controller including automatic printhead

detection. - Award-winning CE-DESIGN 2018 granted.

TECHNICAL SPECIFICATIONS X72

TECHNICAL SPECIFICATIONS X72

Printhead: Seiko 510BN

Printheight: 72 mm

Resolution: 180DPI

Dropsize: 50 Picoliter

Max. print speed:: 45 meters/min

Inktank Capacity: 400 ml

Omnidirectional print direction: Yes, 180 degrees

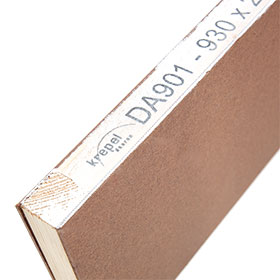

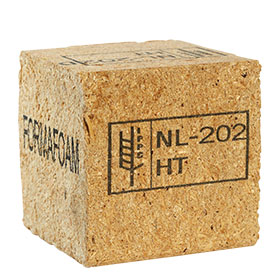

Available Inks: Oil based (mineral free MOSH MOAH)

Controller TsC20: 20cm Touchscreen + Windows OS