Cardboard uncoated

Properties of cardboard

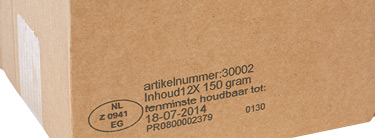

Cardboard has an open fiber structure that absorbs ink well. This porous surface therefore makes oil-based ink the most suitable agent for coding. The oil is almost immediately absorbed by the cardboard, leaving the dye on the surface. By far, in most cases this is for (outer) boxes which in turn, are packed with individual products. These boxes are often provided with a barcode, address details and a description of its contents.

Coding techniques suitable for cardboard

Hi-Res Inkjet is by far the most commonly used coding technique for boxes. Because printing is done directly onto the cardboard, individual costs per print are much lower than labels. In addition, Hi-Res Inkjet can be controlled digitally making it possible to automatically print variable information for every box. This can be done by internal functions of the printer itself, but also from an ERP or external database. If the print does not need change because only a permanent logo or text is to be printed for instance, then a Rollcoder offers an economical alternative.