Automate printjobs

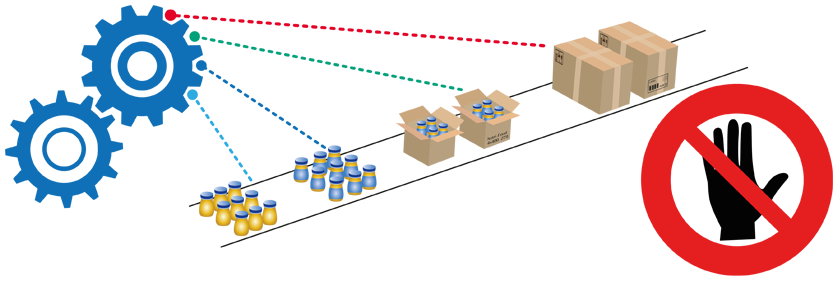

Automatically configure the complete line in one action

Automation of the coding process is achieved by pre-setting all print job parameters. These settings are then linked to a specific production run. When starting the production run, the parameters are sent to the printer(s) via the network. This can be done either directly from the ERP, but also from a PC. Apart from the fact that downtime from repeated manual entries is prevented, no more human configuration errors will be made when restarting a run.

Automatic print job selection and interim controls

After starting the production run from the central PC/ERP no further (manual) action is required. Despite this, manual operator input or a control step can be added into the process if required. This naturally also applies to automated checks or visual/weighing checking equipment. In this way, the printing process can be set up modularly according to any coding need, thus allowing specific causes for errors to be covered.

Downloads

- Drivers: Kortho

- Software: Nicelabel Label Management Software

- Leaflet: Kortho Software leaflet