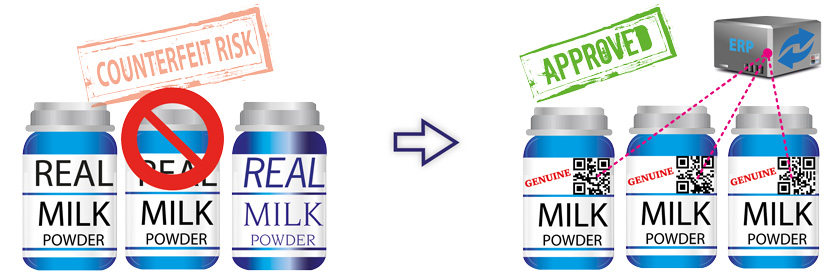

Serialization

Provide each product with a unique tracing code

Serialization is a process that is used to guarantee traceability. This is achieved by providing every individual product with a unique (2D) barcode during production. At the same time a log will be made of all these codes. Each product can then be identified by their unique code. Traceability then is guaranteed by at a later stage being able to compare the log with the actual codes on the products.

Generate barcodes in real-time while printing them at the production line

Each Kortho printer has a internal barcode generator that supports more than 113 different barcode types. Becouse of this the barcodes can be generated from internal variable counters or converted from a data strings which are sent to the printer. This string could for example be sent from an extenal database or PLC. Becouse the barcodes are generated at the production line very fast printing speeds can be achieved. Apart from custom log functionalities from the ERP, logging can also be done by vision equipment or by our software. In this case each print will be stored simultaneously as the printer makes the print.

Downloads

- Drivers: Kortho

- Software: Nicelabel Label Management Software

- Leaflet: Kortho Software leaflet