Plastics

Properties of plastic

Beside the fact that plastics have smooth, non-porous surfaces, many types of plastic contain oil derived/greasy constituents that make this material “sweat”. This makes coding relatively difficult. The use of solvent-based inks is therefore required. The solvent will evaporate almost instantly after applying the coding, after which only the dye remains. These prints are therefore permanent. An alternative option is to work with thermal transfers or wax-based inks. In all of these techniques, bonding occurs due to temperature changes.

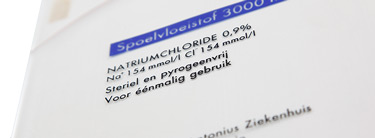

Suitable coding techniques for plastic

Permanent coding of plastic requires the use of Hi-Res Inkjet in combination with solvent-based ink. Wax or resin based techniques such as Hot Solid Inks, Thermal Transfer or Hotprint also provide good bonding because the ink/dye is applied in a molten state, but then immediately cools down and solidifies on contact. Printing done with Hot Solid Inks can therefore also be removed by rubbing/heat. Hotprint provides the most permanent print option because this printing process involves high temperatures and pressure.